| Last Post |

Filip CZ

|

|

Art Love

|

|

1/21/2014 4:56 PM

|

|

Ryan,

I've asked Tom Hanson for an update on 6.3 water pump parts citing your experience with the thrust ring. I can't easily find what we paid for the shafts. I've done an e.mail search of what E.mails I have archived and it doesn't come up. I'll send Tom another e.mail asking for a P&A and price for the shaft specifically.

Art

|

|

|

|

S class

|

|

1/21/2014 11:55 AM

|

|

Art, the thrust piece was ordered through my local parts guy, and was indicated as ex-Germany stock. After your comment, I phoned my guy today to see if it was actually en route, or if our order had returned an NLA status. Apparently, it has been dispatched from Germany, and there seems no reason to suspect it will not arrive next week with the rest of my order.

Today I queried the price on the shaft. There is a strange system here in South Africa, that if a part has never before been sold locally, its not in the database and has no price associated with it. To get a price, an entry has to be created in the database, and this process requires a VIN, engine number, part description etc. We have begun the process, but I will only get the price in a few days time. In the meantime, I'm tempted to buy the one that Martin linked.

116.036

116.036

116.024

116.028

116.028

107.044

202.026

|

|

|

|

Art Love

|

|

1/21/2014 6:55 AM

|

|

Ryan, was that through M-B? Maybe they have remanufactured them because they were NLA a year or two ago. I'll ask Tom again about what they have for 6.3 water pumps currently.

Ron, are you talking about the sliding seal?

Art

|

|

|

|

Ron B

|

|

1/21/2014 1:43 AM

|

Art, i go that seal place at Annie St,Rocklea where I can buy any type of seal ever made. Really reasonable costings too. A seal for a Mercedes pump costs me $10. They can supply the ceramic seal faces and if needed, can reface damaged ceramic and mettalic running faces.  quote:

12-14-2004, 11:49 PM #8

Tom Hanson

MBCA Member

What the heck, try to stuff a MB 6.9 liter V8 in it. What a machine that would be..

__________________

Tom Hanson

Orange County Section

|

|

|

|

S class

|

|

1/21/2014 1:17 AM

|

|

I have ordered a new one of the stainless thrust ring that goes into the impeller, I was lead to believe that availability was not a problem. Quoted price was approx $25.

116.036

116.036

116.024

116.028

116.028

107.044

202.026

|

|

|

|

Art Love

|

|

1/20/2014 9:03 PM

|

|

Martin,

The shaft really isn't the problem. As you say, it is easily machined from billet. The new ones from Tom were not expensive - I don't know how many M-B have left. The problems are the sliding seal, at least temporally available as long as M-B still stock that version from the diesel, and the impeller. The last time I checked, the 6.3/600 impeller was NLA except in the few remaining 600 full repair kits. They could be cast using existing units as a pattern and allowing for shrinkage. The chromed seal ring in the impeller is also NLA, just the rubber seal ring. One of Justin's chrome seal rings has a tiny crack in it, probably enough to produce a tiny weep. They could be re-manufactured in stainless I guess.

Art

|

|

|

|

Martin L

|

|

1/20/2014 6:44 PM

|

|

Perhaps we should buy that new shaft Jack and have some made by copying it.

300SEL 6.3 #6481

420SEL W126

|

|

|

|

Jack English

|

|

1/20/2014 6:26 PM

|

|

Martin, This same vendor offers a pump rebuild for US$375.00 when you send in your pump; I think they pull a rebuilt off the shelf and send it right away. Others sell for about the same US$675 with a refundable US$200 core charge. That still might seem expensive for those who just want the parts to rebuild their own. As John Hubertz suggests, a run of parts and we could assemble and sell a rebuild kit through our store site.

Jack English

300SEL 6.3 #4768

|

|

|

|

Martin L

|

|

1/20/2014 4:16 PM

|

|

A new shaft.

http://www.ebay.com.au/itm/MERCEDES-M100-300SEL-6-3-OR-600-NEW-ORIGINAL-WATER-PUMP-SHAFT-1002020605-/130704879244?pt=Motors_Car_Truck_Parts_Accessories&hash=item1e6e9e2e8c

Rebuilt pump....expensive!

http://www.ebay.com.au/itm/1970-1971-1972-mercedes-benz-water-pump-300-sel-6-3L-OEM-aluminum-2yr-wrnty-/161182389573?pt=Motors_Car_Truck_Parts_Accessories&hash=item2587381545

300SEL 6.3 #6481

420SEL W126

|

|

|

|

CraigS

|

|

1/20/2014 3:03 PM

|

|

I have just had my 6.3 water pump rebuilt in Melbourne, and the cost was $300 with freight. I don't know what they do, or how they do it, but it certainly works perfectly and at a reasonable cost.

|

|

|

|

fullhappyfish

|

|

1/20/2014 3:03 PM

|

This is a serious question: With modern-day 3d imaging and printing capabilities, wouldn't it make more sense to copy an existing housing in good condition? Once you had a plastic copy, easy peasy design a simple and robust shaft and make the impeller a lifetime version using modern heavy truck materials. I have a couple of contacts in China that might even produce a run to sell over the next 50 years if someone wants to go that far. John Hubertz 1977 450SEL (Max Headroom)

|

|

|

|

S class

|

|

1/20/2014 9:47 AM

|

OK, so I think the penny has dropped. The photo below shows the components of the new seal. Of the three components on the pen, the left-most is a dust cover which is removed. The central component is a thrust ring, with the ID of 14.2mm, which I had assumed I would need to use. But if I understand correctly, this is only the case in its intended use in the diesel motor. For the 6.3, it is not required, as its function is fulfilled by the stainless thrust piece in the impeller. Hope this is correct? The right most of the three components is the seal itself, and its self evident how it is to be installed.

116.036116.036116.024116.028116.028107.044202.026

|

|

|

|

S class

|

|

1/20/2014 9:28 AM

|

|

Art, I receive the lode stars only sporadically. I have been a member for a while, but I think that has now expired.

I know I need to remove the plastic cover from the seal assembly. However, it seems that the ID of the new seal is way to small to go over the end of the shaft where the impeller sits, let alone the thicker portion where the seal is supposed to run.

116.036

116.036

116.024

116.028

116.028

107.044

202.026

|

|

|

|

Art Love

|

|

1/20/2014 3:57 AM

|

|

Yes,

There is a 2 part article in 2 Lode Stars on this topic, as well as what I have posted on this website since that old thread. I thought you were a member so you would have the Lode Stars. That seal is the correct size for the shaft. You need to take the protective plastic cover off the seal to measure the ID. The other thing to appreciate is that it is not critical for the shaft to be in perfect condition where the seal sits, because the seal is not between the shaft and the seal, but between the seal face and the corresponding chrome seal ring in the impeller.

The corrosion of the shaft is a good indication that this pump has been leaking for a long time. When last I checked, new shafts were still available and a lot less expensive than repairing that shaft. But in reality, it is more a cosmetic issue than a functional one that the shaft should look a lot better than it does except where the seal sits to ensure it rides well against the impeller seal ring face.

Art

|

|

|

|

S class

|

|

1/20/2014 12:58 AM

|

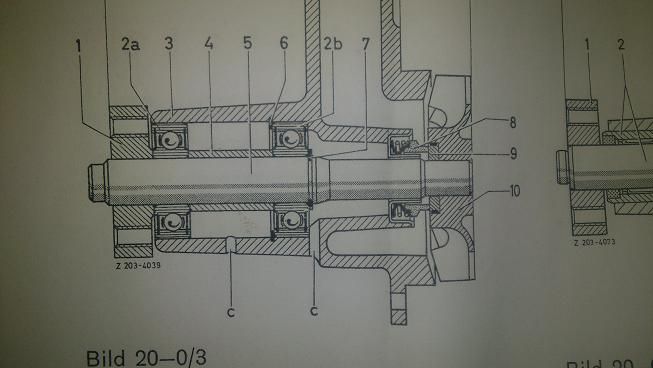

I need to overhaul the pump from a 100.981 motor. I did a lot of searching on this board, and found this thread : http://www.m-100.co/forum/topic.asp?TOPIC_ID=2332&whichpage=1&SearchTerms=waterIn this thread there is discussion about the non-availability of the original seal, and the proposal to use a seal from a more recent diesel engine. I duly stripped the pump, and ordered bearings and the suggested replacement seal.   Its quite clear that my shaft is in a poor state in the area where the seal runs. You can see that the shaft is in that location similar in diameter to where the impeller is pressed on. Referring to the WS manual drawing :  the shaft should in fact be a good deal thicker where the seal runs. I was intending to have the shaft built up, but now that the new seal has arrived, I can see that it is intended for a smaller diameter shaft. So I need to have the shaft machined appropriately, and built up where needed, then chromed I suppose.  The ID of the seal appears to be 14.2 or 14.3mm. What diameter should I specify for the shaft?  Has anyone completed this project successfully? Thanks in advance.

116.036116.036116.024116.028116.028107.044202.026

|

|

|

|