| Last Post |

Filip CZ

|

|

11/9/2019 1:52 PM

|

There is MB replacement for this bolts A1149900010.

300SEL 6.3 #1285 (1969 EURO version)

300SEL 6.3 #5346 (1971 US version with engine KO)

|

|

|

|

6.3Nut

|

|

10/14/2019 1:03 PM

|

|

|

|

|

|

Art Love

|

|

10/13/2019 6:03 PM

|

|

I suggest you take one of the original bolts to a nut and bolt supplier and ask if they can match it.

Art

|

|

|

|

6.3Nut

|

|

10/12/2019 10:58 PM

|

Thanks. The bolts arrived, and the news is not good. The bolts have star head, something like a inside out trox. My concern is in that tight spot how are we suppose to use a trox box head wrench. Any one has any other part number for a flanged hex nut that can be used . This is orig part number 900170008016 which has been replaced by 000000-000276

|

|

|

|

cth350

|

|

10/12/2019 8:50 AM

|

|

there have been a time or two when I wanted to saw down a long bolt to replace a shorter one that I didn't have handy. Seems maybe that your car's PO did that twice.

The correct bolt has a built in flange. Do any of these bolts have that slightly wider shoulder? If not, that would be another sign that they were the ones available as opposed to the ones needed.

-CTH

|

|

|

|

6.3Nut

|

|

10/9/2019 8:26 PM

|

I have ordered 4 bolts for the fan pulley to replace the damaged ones. What I have noticed with the old ones is, two are shorter than the others and they looked sawed. Is this something that is standard or the previous owner was trying to make life easy? With the shorter length, the bolts come out without moving the fan, while to get the long ones out one has to pull the fan away from the pulley to make room.

|

|

|

|

6.3Nut

|

|

10/25/2018 3:34 PM

|

quote:

Originally posted by Chris Johnson

The water manifold (aka water pump base) is almost always badly corroded after all these years and, as stated above, I would remove it with the water pump and then remove the water pump from it.

There are a total of ten bolts that hold the water manifold to the front of the engine and, as Art indicates, a couple of these can only be accessed by turning the recess in the vibration damper so that it aligns with these bolts. Seven of these bolts are hex socket heads (Allen head) and , as Ron states, these must always have the head cleaned out before inserting the tool and trying to loosen them. Not doing so risks having the tool bit not seat fully in the head and can strip out the head during loosening. This must be done on any of the hex socket head screws anywhere on the car.

It's not an easy chore, but you should seriously consider replacing the front crankshaft seal once you are into things this far. Along with total resealing of the water manifold, the opportunity for insidious oil leaks at the front of the engine is virtually eliminated. Other oil leaks in this vicinity are easy to fix in comparison.

You should also consider replacing the motor mounts at this time as well since it will never be easier than it is right now. On the other hand, they ain't cheap so you might wait if there are a substantial number of other chores that need to be attended to that would soak up lots of cash since the bad motor mounts won't prevent getting the car on the road.

Chris Johnson

If you aren't constantly impressed with your car, then it needs fixing.

100.012-12-000790

100.012-12-000867

www.300SE.org

Chris, reading your comment, I think I will change the front crankshaft seal too, since I have the radiator and all the hoses removed. I have a 300 ft-lb air impact wrench and a 50mm socket (All the way from UK),for this job. My only scare is any filing I have to do on the shaft where the seal sits - Can I get away with not using any filing? There cars and then there are BABIES! 1969 Euro Model 10901812000931

|

|

|

|

EugeneGroysman

|

|

12/8/2016 5:30 AM

|

|

Art,

Thank you for reply. I was able to locate all needed parts locally.

I got my rebuild air-suspension components back from Martin. Waiting for rebuild injection pump from CA shop.

1971 300SEL 6.3

1965 220SE

1987 BMW M6

1990 Porsche 911 C2

1970 300 sel 6.3

|

|

|

|

Art Love

|

|

11/23/2016 7:22 PM

|

|

Jim,

Yes, he had 3 made if my memory is correct and Martin in Sydney bought one. Justin said he has one left, but could easilly get more done. The only problem I recall was getting the angle right at the front end, so that the pipe lined up perfectly with the short pipe on the water pump. I think I covered that in my postings on his car or it could have been in my thread on working on M100 motors without going and looking it up. I suspect that the one left needs that angle corrected.

Regards,

Art

|

|

|

|

Art Love

|

|

11/23/2016 7:11 PM

|

|

Eugene,

Justin's price is Aust$100 per stud which covers his costs. The A$ is currently selling for about 74US cents. So that is about US$74 [varies a little on a daily basis] each and you need 16 for your motor and you would have to add freight from Brisbane to New York.

Justin also said that he tried recently to get new ball studs from Tom for a 280SL M130 motor that he is rebuilding and Tom told him there was nil stock. He said if the M100 studs were re-manufactured, they would come in at about US$150 each. You could check with Kienle in Germany as to whether they have any as they rebuild a lot of 600's and do sell spare parts. That would give you another price if they have any for sale.

If you want to go ahead with Justin, let me know on artlove@bigpond.net.au and I shall give you his e.mail address so you can deal with him directly.

P.S. ERROR I have spoken today with Justin who checked his old paperwork and the price is A$100 a pair, not per stud. That is A$800 a set of 16, not A$1600. He apologises for the error.

Art

|

|

|

|

james lawson

|

|

11/23/2016 11:30 AM

|

|

Art, did Justin ever get water pipe in the valley made out stainless steel? You had mentioned he might have multiple copies made available.

Jim

jim

|

|

|

|

EugeneGroysman

|

|

11/23/2016 10:08 AM

|

|

Art,

Please ask Jistin about a set of ball studs.

Thanks, Eugene

1971 300SEL 6.3

1965 220SE

1987 BMW M6

1990 Porsche 911 C2

1970 300 sel 6.3

|

|

|

|

Art Love

|

|

11/21/2016 5:22 PM

|

|

Tom Hanson has the camshaft rockers and the chain tensioner at the Classic Center in Irvine, CA. There has been quite a lot written on this forum about replacing the chain tensioner or just cleaning and re-using the one you have. Apparently a number of new ones supplied by M-B a few years ago did not perform properly from what others reported. I did not have that experience. The engine rebuilder whom you have contracted should be able to advise you.

Art

PS The other wear item associated with the camshafts is the ball stud that the rocker engages, and they are NLA. People report using the ball studs from the M189 which are a little shorter or alternately, my son-in-law Justin has had several M100 sets made to original factory specifications including analysis of the metal and can supply you with a set if you need them. I can ask his price if you are interested.

|

|

|

|

EugeneGroysman

|

|

11/21/2016 10:31 AM

|

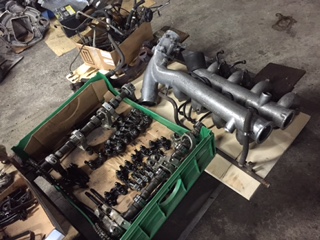

I brought my car to a shop to sort the airsuspension out, ended up rebuilding fuel injection pump and the engine:))       I sent air suspension components to Martin and the pump to Jerry Fairchild Industries for rebuild. Can someone help me to source those parts,   Thanks, Eugene 1971 300SEL 6.3 1965 220SE 1987 BMW M6 1990 Porsche 911 C2 1970 300 sel 6.3

|

|

|

|

Art Love

|

|

4/19/2016 6:06 PM

|

|

I had to Google kpm to ft/pds and 40 came to 289 if I got it right. I am not the best person to answer your question. I am not a mechanic.

Art

|

|

|

|

6.3Nut

|

|

4/17/2016 9:04 PM

|

quote:

Originally posted by Art Love

The number I have is 004 997 21 46, but if you tell Tom that you want a front crankshaft seal for your 6.3, he will know.

If you are going to do that job, then you will need a big hex socket to go on the large nut inside the front pully (I think it is 45mm off the top of my head - measure it) and either an impact wrench (air or electric) or a very long arm, such as a length of water pipe, to fit over the end of your socket wrench. The tightening torque on that nut is 40kpm, 4-20 times greater than any other nut or bolt on the car.

There are also a couple of other critical points in reattaching the damper and pulley that Chris or Ron can cover. If you are going to do that, then removing the pulley and damper will give you access to all the water pump bolts.

Art

Art, I am thinking of working on the seal and wanted to know if I can use an impact wrench with 200 - 300 Ft-lb torque to tighten the nut, will it be safe for the crank[?] There cars and then there are BABIES! 1969 Euro Model 10901812000931

|

|

|

|

EugeneGroysman

|

|

7/22/2015 9:01 PM

|

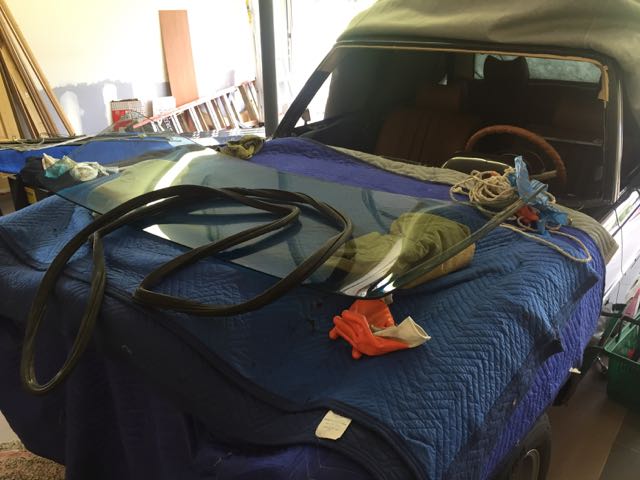

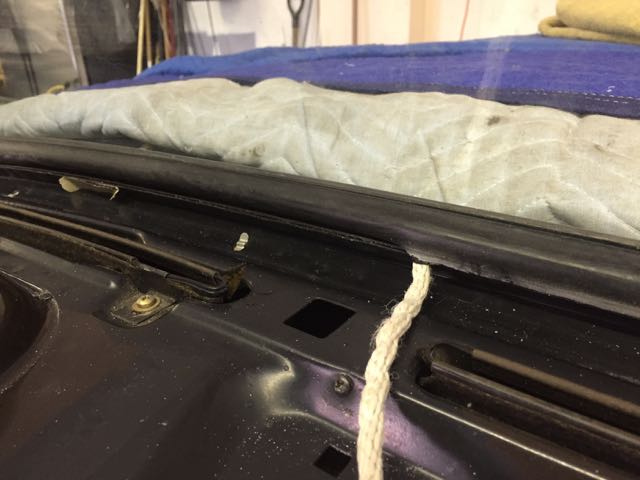

Thank you for replies. Did it all over again:) Windshield is out  Chrome cover plates are on the A pillars  Chrome is in   View from inside  Windshield is in   Installed last pieces in the back  and the front  Add some atf to transmission and gave her a spin around a block. What a difference!  I have 1987 BMW M6 and i like it a lot. But W109 is so fast! And so much fun to drive! 1971 300SEL 6.3

|

|

|

|

olliw109

|

|

7/22/2015 3:05 AM

|

|

Chrome needs to go into the rubber before installing, cant believe it works to get it in properly later! Way too expensive to experiment....

Better luck next time.....

300 SEL 6.3 3478+5327

Oliver

|

|

|

|

Art Love

|

|

7/22/2015 12:05 AM

|

Eugene, Great to see your progress. The correct way to check the ATF level is to have the engine running at operating temperature and check the level of the ATF with the engine running and the gear shift in Park. It should be between the two marks on the Auto dip stick. If the level is low, the shift will slip and flair, especially when going round corners. Two things bother me in your pictures. I am worried that you have not replaced the chrome cover plates on the A pillars before you installed the windscreen. I can't see the left one - looks like body colour- in the close up. Justin nearly did this on #5810 before I stopped the installation. I don't think you will get the chrome A pillar covers on with the windscreen seal in place. Difficult at least. I also believe that you should install the chromed alloy trim strip into the groove in the windscreen rubber prior to installation. Same difficulty with trying to put it in with the windscreen in place. Maybe someone else has achieved that. Others may wish to comment.  Art

|

|

|

|

EugeneGroysman

|

|

7/21/2015 11:40 PM

|

Finally, I had time to work on my car! Here some pics of small progress I made today. Tutorials are from youtube videos. Recommended as two people DIY. I've never done this before but I managed to do it by myself.     From inside the car  Final result, front  and back  I made a couple of laps around my block. Transmission slips. I added ATF, some improvement but still slips. How to check and add ATF correctly? Any recommendations to fix it. Thanks, Eugene. 1971 300SEL 6.3

|

|

|

|